Introduction

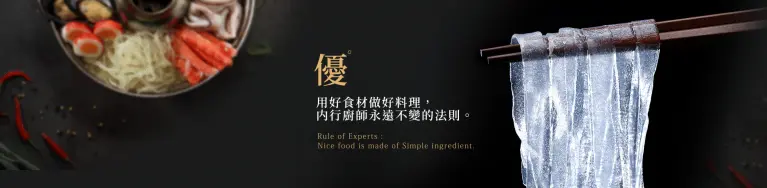

Unique art and specialized technique, Root in Taiwan with Fresh Thought巔 Since 1949, Jung-Nung has always hold faithful beliefs. With three generations of pragmatic steps, we have tried our best to let everyone taste the delicacy and healthy which is supposed to be. |

| Establish internal audit standards for quality assurance and introduce international food safety management system into the whole plant Through ISO22000, HACCP, S9001 and other international certification. In order to pursue higher and better quality, we purchased relevant inspection equipment, implemented independent inspection and audit quality control, and ensured that the quality of manufactured products meets hygienic standards. |

| The largest production capacity in the country In 2014, in response to the increase in production capacity of winter noodles and the need for comprehensive modernization, the Zhongnong Nangang Plant, which covers an area of about 3,000 ping, was completed in 5 years with an investment of 800 million yuan in Nangang Industrial Zone, Nantou City. Nangang Factory has the most advanced and largest-scale equipment and the best environment. The winter noodles produced have the highest quality and largest production capacity in the industry, and the production technology and quality are far ahead of the same industry. Nangang Factory, Nangang Industrial Zone, Nanto |

| World-class operating environment, a leading Cellophane Noodle company In line with international hygiene standards, the "Jung Nung Bean Thread.Ltd" has created an international-standard operating environment for Taiwan's traditional winter noodle industry. JungNung hopes to bring a new leading enterprise of vermicelli in compliance with food safety to Taiwan's traditional food industry. |